ASSY® 3.0 joist hanger screw

ASSY 3.0 joist hanger steel zp FT pan head AW

SCR-PANHD-WO-JOISTHNG-AW20-(A3K)-5X40MM

Art.-no. 015335040

EAN 4045989669684

Register now and access more than 125,000 products

Steel, zinc plated, partial thread, joist hanger screw head, AW recess

Connects the wood instead of splitting it

Reinforced head with enlarged support

High contact pressure

Cylindrical shank reinforcement to the outer diameter below the head

Mechanically interlocking connections for sheet preforms and high shear-off values

Asymmetrical coarse thread

Fast creation of screw connections and high pull-out values

Patented tip with counter thread

Reduced splitting, fast gripping and precise positioning

AW recess

Wobble-free and secure screw positioning

Material

High-strength steel for high breaking torque/zinc plated, blue passivated (A2K).

The screws are not suitable for outdoor use or for rooms subject to short-term or continuously high humidity levels! Please use ASSY 3.0 A2 stainless steel screws in these cases.

To attach metals to wood, machine a precise cut-out in the metal tab.

ASSY 3.0 chipboard screws are optimised for use in engineered wood. Use in plastic anchors may cause a reduction in the admissible load. Therefore, we recommend only using screws without optimised thread tips (drill tip, counter thread, ring thread, serrated edge, self-clearing groove etc.) in plastic anchors, e.g. Würth ASSY D, prefix number 0151 (countersunk head) and prefix number 0153 (pan head).

Available work documents:

Timber dimensioning software, load tables and detailed processing instructions can be found on the service page www.wuerth.de/assy.

ETA-11/0190

Specifications of European Technical Approval ETA-11/0190 and the sheet preform to be fitted must be observed.

Datasheets(X)

CAD data (available after login)

Ideal for sheet preform connections that are to be disassembled again at a later point or for connections with high loads on thin wood cross-sections.

Comparable shear-off values and greater pull-out values compared to 4.0 mm ring-shank nails.

Permitted for sheet preforms with a thickness of 1.5 mm.

Direct attachment of sheet metal and sheet preforms to softwood, engineered wood materials made from softwood, cross-laminated timber, LV and hardwood. Pre-drilling optional in softwood. Hardwood must be pre-drilled according to ETA 11/0190.

Screw-in angle 0° to 90°.

Pre-drilling in solid wood and engineered wood materials made from softwood permitted but optional. Hardwood surfaces must be pre-drilled in accordance with ETA 11/0190 (softwood d = 3.0 mm; hardwood d = 3.5 mm).

| |

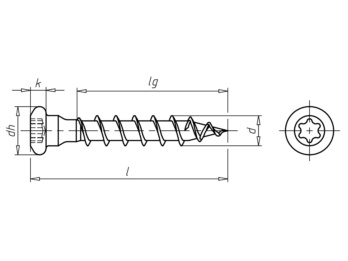

Nominal diameter (d) | 5 mm |

Length (l) | 40 mm |

Head type | Pan head |

Head diameter (dh) | 8 mm |

Head height (k) | 2.6 mm |

Head details | Reinforced shaft neck |

Internal drive | AW20 |

Thread type | Wood screw thread |

Thread design | Full thread |

Thread form | Coarse thread |

Thread length (lg) | 35 mm |

Core diameter | 3.3 mm |

Shape of tip | Tip with counter thread |

Angle of the tip | 28 Degree |

Material | Hardened steel |

Surface | Zinc plated |

Colour | Silver |

Max. screw-in angle | 90 Degree |

Min. screw-in angle | 0 Degree |

Product weight (per item) | 4.000 g |

Suitable for use in the following materials | Board ply wood (BSP), Wood, Derived timber product, Hardwood, LVL, Softwood |

Area of application | Metal plate, wood |

Approval | ETA-11/0190 |

RoHS-compliant | Yes |

| Characteristic load capacities of ring-shank nails and joist hanger screws in kN in softwood | |||||||||

| Fastener in mm | Characteristic bulk density Pk in kg/m³ | ||||||||

| 350 | 380 | 410 | 430 | ||||||

| Fv,RK | Fax,RK | Fv,RK | Fax,RK | Fv,RK | Fax,RK | Fv,RK | Fax,RK | ||

| Würth ring-shank nail | 4.0x40 | 1,68 | 0,74 | 1,82 | 0,78 | 1,95 | 2,05 | 1,11 | |

| 4.0x50 | 1,99 | 0,98 | 2,17 | 1,16 | 2,33 | 2,41 | 1,48 | ||

| 4.0x60 | 2,15 | 1,23 | 2,28 | 1,44 | 2,41 | 2,50 | 1,85 | ||

| 4.0x75 | 2,24 | 1,59 | 2,39 | 1,88 | 2,54 | 2,64 | 2,40 | ||

| 4.0x100 | 2,27 | 1,72 | 2,42 | 2,02 | 2,58 | 2,69 | 2,59 | ||

| Würth ring-shank nail, collated | 4.4x40 | 1,70 | 0,81 | 1,84 | 0,95 | 1,11 | 2,09 | 1,22 | |

| 4.4x50 | 1,88 | 1,08 | 1,99 | 1,27 | 1,48 | 2,19 | 1,63 | ||

| 4.4x60 | 1,95 | 1,35 | 2,07 | 1,59 | 1,85 | 2,29 | 2,03 | ||

| Würth joist hanger screws | 5x25 | 1,49 | 1,20 | 1,58 | 1,28 | 1,36 | 1,74 | 1,41 | |

| 5x30 | 1,69 | 1,50 | 1,80 | 1,60 | 1,70 | 1,99 | 1,77 | ||

| 5x35 | 1,91 | 1,80 | 2,04 | 1,92 | 2,04 | 2,26 | 2,12 | ||

| 5x40 | 2,13 | 2,10 | 2,29 | 2,24 | 2,38 | 2,46 | 2,48 | ||

| 5x50 | 2,29 | 2,52 | 2,41 | 2,69 | 2,86 | 2,59 | 2,97 | ||

| 5x60 | 2,44 | 3,12 | 2,57 | 3,33 | 3,54 | 2,76 | 3,68 | ||

| 5x70 | 2,58 | 3,66 | 2,71 | 3,91 | 4,15 | 2,92 | 4,32 | ||

| Design value for load capacity: Fi,Rd= Fi,Rk x kmod / Ym with Ym = 1.3 | |||||||||

| Calculation for the Würth ring-shank nail in accordance with DIN EN 1995-1-1. Pull-out capacity for load capacity class 3 in accordance with DIN EN 1995-1-1/NA. Würth joist hanger screws in accordance with ETA-11/0190. Thickness of the sheet preform: 2 mm. | |||||||||

| Minimum clearances for joist hanger screws ∅ 5 mm for sheet steel-wood connections | |||||||

| pk < 420 kg/m3 | pk < 500 kg/m3 | Default value | |||||

| Force II in the direction of the grain | Force ┴ in the direction of the grain | Force II in the direction of the grain | Force ┴ in the direction of the grain | Force II in the direction of the grain | Force ┴ in the direction of the grain | ||

| a1 | in the direction of the grain | 8.4 d | 3.5 d | 10.5 d | 4.9 d | 3.5 d | 2.8 d |

| a2 | perpendicular to the direction of the grain | 3.5 d | 3.5 d | 4.9 d | 4.9 d | 2.1 d | 2.8 d |

| a3,t | stressed end of the end grain | 15 d | 10 d | 20 d | 15 d | 12 d | 7 d |

| a3,c | unstressed end of the end grain | 10 d | 10 d | 15 d | 15 d | 7 d | 7 d |

| a4,t | stressed edge | 5 d | 10 d | 7 d | 12 d | 3 d | 7 d |

| a4,c | unstressed edge | 5 d | 5 d | 7 d | 7 d | 3 d | 3 d |

| Minimum clearances for ∅ 4 mm and 4.4 mm ring-shank nails without pre-drilling for sheet steel-wood connections | |||||

| pk < 420 kg/m3 | pk < 500 kg/m3 | ||||

| Force II in the direction of the grain | Force ┴ in the direction of the grain | Force II in the direction of the grain | Force ┴ in the direction of the grain | ||

| a1 | in the direction of the grain | 7 d | 3.5 d | 10.5 d | 4.9 d |

| a2 | perpendicular to the direction of the grain | 3.5 d | 3.5 d | 4.9 d | 4.9 d |

| a3,t | stressed end of the end grain | 15 d | 10 d | 20 d | 15 d |

| a3,c | unstressed end of the end grain | 10 d | 10 d | 15 d | 15 d |

| a4,t | stressed edge | 5 d | 7 d | 7 d | 9 d |

| a4,c | unstressed edge | 5 d | 5 d | 7 d | 7 d |

| According to the following table, ring-shank nails can be replaced by joist hanger screws in the event of a shear force load | ||||

| Ring-shank nails [mm] | ASSY 3.0 joist hanger screws [mm] | |||

| Characteristic bulk density rk in kg/m3 | ||||

| 350 | 380 | 410 | 430 | |

| 4.0x40 | 5x30 | 5x35 | 5x35 | 5x35 |

| 4.0x50 | 5x40 | 5x40 | 5x40 | 5x40 |

| 4.0x60 | 5x50 | 5x50 | 5x50 | 5x50 |

| 4.0x75 | 5x50 | 5x50 | 5x60 | 5x60 |

| 4.0x100 | 5x50 | 5x60 | 5x60 | 5x60 |

| The different minimum clearances must be observed! | ||||

| Characteristic load capacities of joist hanger screws in pre-drilled holes in hardwood in kN | |||||||

| Fastener in mm | Characteristic bulk density Pk in kg/m³ | ||||||

| 530 | 540 | 550 | |||||

| Fv,RK | Fax,RK | Fv,RK | Fax,RK | Fv,RK | Fax,RK | ||

| ASSY 3.0 joist hanger screws | 5x25 | 2,74 | 1,67 | 2,78 | 1,70 | 2,83 | 1,72 |

| 5x30 | 2,84 | 2,09 | 2,89 | 2,12 | 2,93 | 2,15 | |

| 5x35 | 3,17 | 2,51 | 3,20 | 2,55 | 3,23 | 2,58 | |

| 5x40 | 3,27 | 2,93 | 3,30 | 2,97 | 3,34 | 3,01 | |

| 5x50 | 3,42 | 3,51 | 3,45 | 3,57 | 3,49 | 3,62 | |

| 5x60 | 3,63 | 4,35 | 3,67 | 4,41 | 3,71 | 4,48 | |

| 5x70 | 3,81 | 5,10 | 3,86 | 5,18 | 3,90 | 5,25 | |

| Design value for load capacity: Fi,Rd= Fi,Rk x kmod / Ym with Ym = 1.3. | |||||||

| Only valid for Würth joist hanger screws according to ETA-11/0190. Thickness of the sheet preform: 2 mm. | |||||||

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!