Plastic frame anchor WD10

Plastic frame anchor WD10 without screw

ANC-(WD 10)-PLA-WO.SCR-10-10X100

Register now and access more than 125,000 products

- Push-through installation

- Immediate load-bearing capacity – no waiting

- Compatible anchor sleeve and screw

- The hammer-in stop prevents premature expansion of the anchor during installation

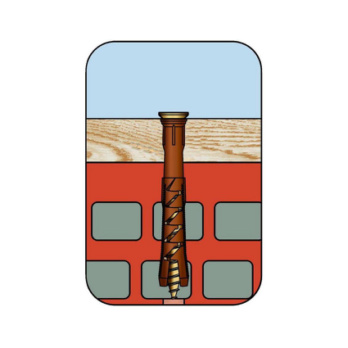

- Anchorage via friction locking between anchor sleeve and anchoring base

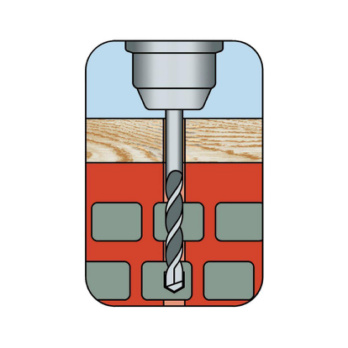

Create the drill hole

Create the drill hole

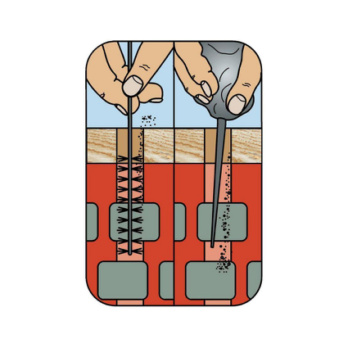

Clean the drill hole

Clean the drill hole

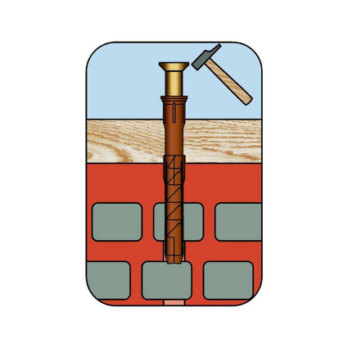

Set anchor and screw

Set anchor and screw

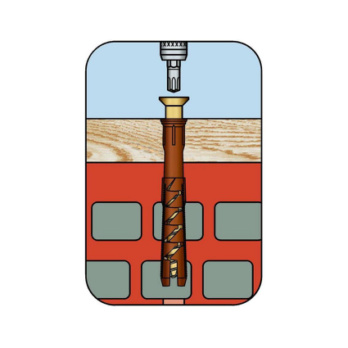

Screw in the screw

Screw in the screw

Screw in screw until flush

Screw in screw until flush

The anchor is approved for multiple attachment of façade cladding

WD10 is approved for anchoring in the following bases: Masonry walls (perforated sand-lime brick, vertically perforated brick, hollow lightweight concrete blocks, solid bricks and blocks made of lightweight concrete, no-fines lightweight concrete (TGL), standard concrete cladding made of three-layer external wall panels

Installation temperature: Temperature of anchoring base ≥ 0°C

The stainless steel screw can be used outdoors, in industrial atmospheres and in coastal areas

The galvanised screw can be used outdoors or in industrial atmospheres, if the area around the screw head is protected against moisture or rain to ensure that no moisture can penetrate the anchor shaft (suitable paint or plastic caps)

Suitable for attaching façade substructures (made of wood or steel), wooden beams, wooden laths, metal rails, angle brackets, profiles etc.

Anchor diameter | 10 mm |

Anchor length (l) (I) | 100 mm |

Max. attachment height (d a) (da) | 10 mm |

Nominal drill-bit diameter (d 0) | 10 mm |

Drill hole depth (t) | 100 mm |

Anchoring depth (h v) | 90 mm |

Datasheets(X)