For detailed information, other images and documents, please select individual articles from the following table.

MIG soldering system CuSi 150

MIG soldering system for welding galvanized, high-strength and coated sheet metal in in automotive companies and body shops. Thanks to minimal heat transfer during this process, the sheet metal cannot bend and the corrosion protection is retained in the process.

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

Call customer service: +420 323 041 141

Prices for customers after login

MIG soldering procedure

- The basic properties of the work piece are retained

- Bending behaviour and thermal expansion of the work piece are not affected by soldering

- Decreased splash formation - reduced reworking

- Minimal pore formation - high seam strength

- High welding speed

Soldering system

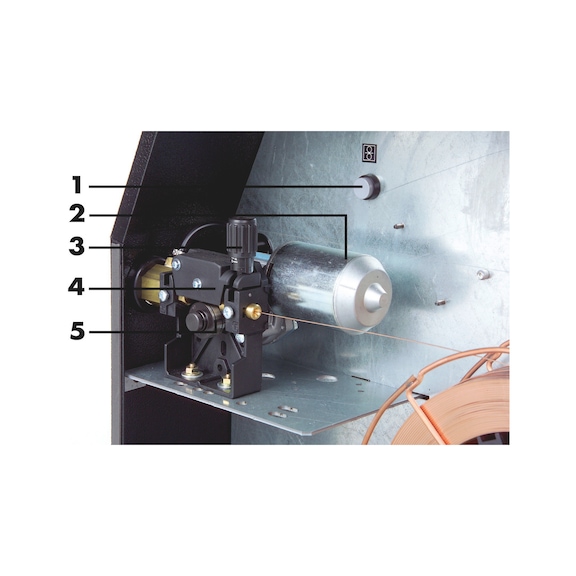

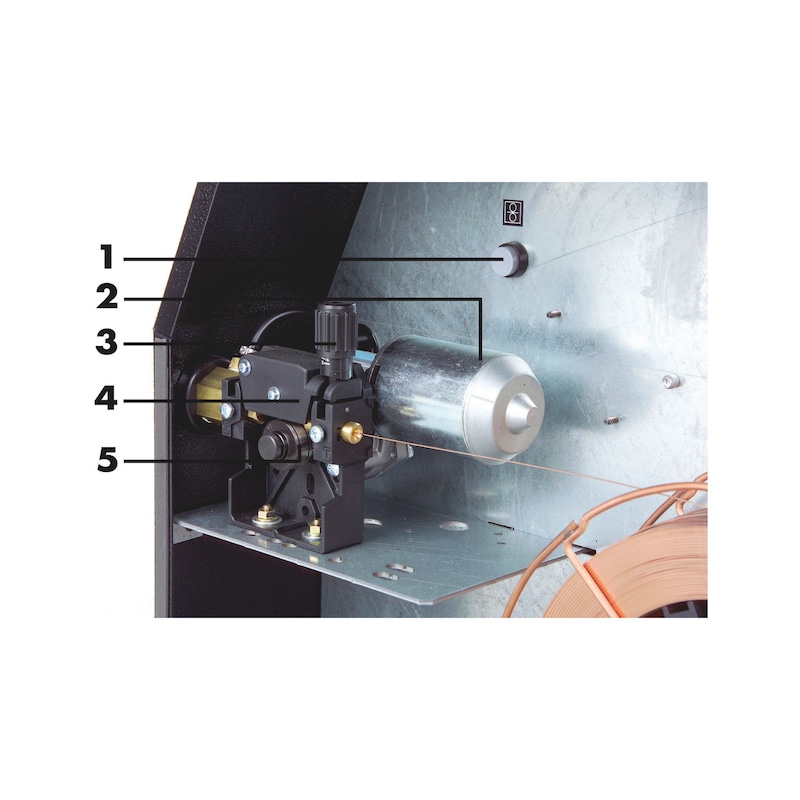

- Processor-controlled adjustment of welding current, wire feed, wire burnback, post-purge gas flow and spot welding time

- Optimised fan cooling allows system to remain switched on for longer

- Overload-proof rectifier

- Automatic roll drive for threading in wire

- Can be switched between 2/4-cycle spot welding

- 5-year warranty on main transformer

Soldering and welding range 15–150 A/14.8–21.5 V

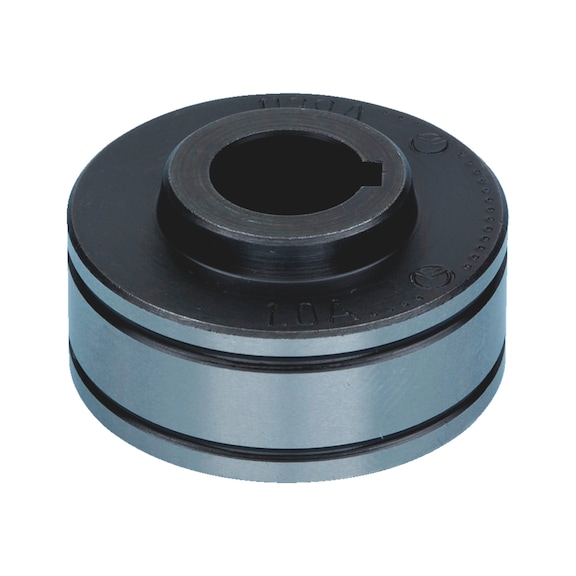

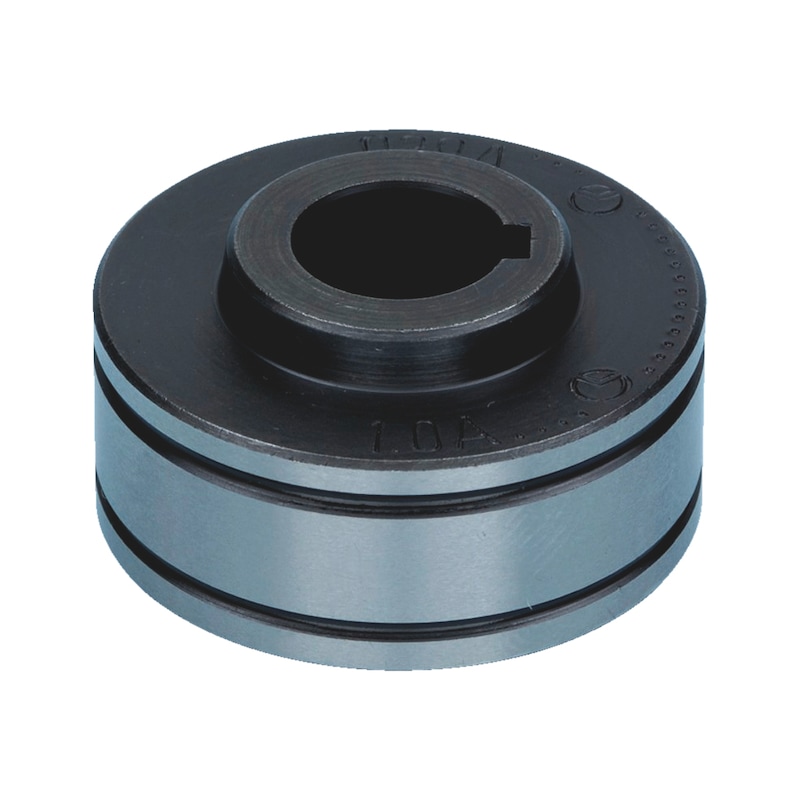

Feed unit - 2-roller drive

Switch-on time at max. current (40°C) 40%

Welding current at 60% switch-on time (40°C) 120 A

Welding current at 10% switch-on time (40°C) 100 A

Weldable CuSi wires 0.8–1.0 mm

Weldable steel/VA wires 0.6–0.8 mm

Weldable aluminium wires 1.0 mm

Wire feed speed 1–23 m/min

Markings CE,S

MIG soldering

Guideline value for flow rate in l/min: Wire Ø x 10 = l/min

Hose package must be converted from PTFE cores to process aluminium and stainless-steel welding wires.

Appropriate gas for MIG welding: 100% argon

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!